Pramp Automation and Calibration

Category: Level

Product: Level Gauges

Sub Product: Reflex Level Gauge

This instrument consists of a metal body, machined to have an internal chamber and one or more front windows (on one side only of the gauge). On each window a special high resistance plate reflex glass is fitted with sealing joint and metal cover plates hold by bolts and nuts. The chamber is connected to vessel with cross fittings and flanged, threaded or welded ends. Usually, between the instrument and its connecting ends, valves are fitted to consent shut-off piping and to disassemble the level gauge without emptying the vessel. Drain valves can also be fitted to cross fittings device. To avoid leakage in case of glass breakage, safety ball-check device can be provided.

Working principle

Reflex level gauges working principle is based on the light refraction and reflection laws. Reflex level gauges use glasses having the face fitted towards the chamber shaped to have prismatic grooves with section angle of 90°. When in operation, the chamber is filled with liquid in the lower zone and gases or vapours in the upper zone; the liquid level is distinguished by different brightness of the glass in the liquid and in the gas/vapour zone.

Transparent level gauge

Transparent Liquid Level Gauge consists of a metal body, machined to have an internal chamber and one or more front windows (on each side of the gauge).

On each window a special high resistance plate transparent glass is applied with sealing joint and metal cover plate hold by bolts and nuts.

To avoid leakage in case of glass breakage, safety ball-check device can be provided in cross-fittings or shut-off valves. To protect glass surfaces from corrosive action of the process fluid, Transparent Level Gauges can be fitted with CAF, Mica shields or PTFE shields.

Working principle

Fluid level indication is the result of the different transparency property of the two media (i.e. liquid and air or vapour.)

Salient Features:

- Moulded borosilicate Reflex / Transparent glasses, conforming to BS 3463 : 19575 or equivalent standards.

- Screwed bonnet or welded bonnet offset type valves.

- Mica shields for protection against corrosive services.

- Safety ball check, frost free & heating / cooling provide on demand.

- Engraved Scale – Aluminium / Plastic / Stainless Steel.

- IBR certificate in form IIIC can be provided.

- Illimunator – Weatherproof or flameproof.

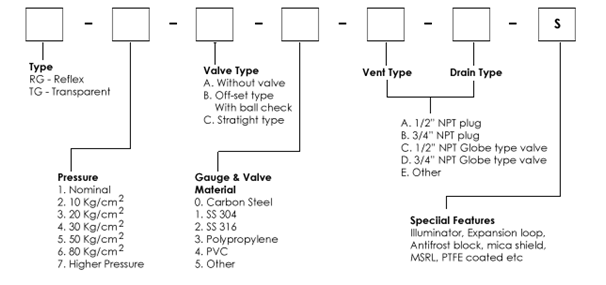

Model number for reflex / transparent level gauge

|

|