Pramp Automation and Calibration

Category: Valves

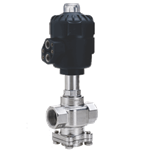

Product: Ball Valve

Sub Product: Pneumatic Ball Valve

Metal Ball Valves Screwed & Flanged End - 2 Way

|

Size: |

15mm (1/2”) to 150mm (6"). |

|

Body and End Piece : |

Investment Casted Cast Steel ASTM A 216 WCB (DIN 1.0619 GS-C 25).or Stainless Steel ASTM A351 CF8 (DIN1.4301) or CF8M(DIN1.4408) (GX6 Cr.Ni MO17.13.3). |

|

Ball : |

Stainless Steel AISI 316. |

|

Design: |

API-6D & API 607 Std. Fire safe design. |

|

Stem and Stem nut : |

Stainless Steel AISI 316. |

|

Ball seat : |

Reinforced PTFE. |

|

Stem seals : |

Reinforced PTFE. |

|

Body gasket : |

PTFE. |

|

Antistatic device : |

Stainless Steel SS 316. |

|

Pressure Temp. rating : |

As per ASME B16.34 Class 300. |

|

Body pressure rating : |

As per ASME B16.34 Class 300. |

|

End Connection : |

Flanged to ASME B16.5 Class 150. |

|

Leakage Class : |

As per ANSI FCI-70-2. Teflon seating Class VI. |

|

Air supply requirement : |

4 to 8.5 bar. (Line fluid pressure dependent). |

|

Characteristic : |

On-Off. |

|

Temperature : |

Continuous 180°C with Bracket mount. |

|

Double Acting : |

"D" - NC/NO |

|

Spring Return : |

S" - NC/NO |

|

Manual Operation : |

Provision for manual Hand- lever (optional) type for ACT-63-D/S actuator. Manual hand gear operator for ACT-90-D/S onward. |

|

Accessories : |

Local position indicator, Rotary Limit Switch box, Air Lock Relay, Solenoid Valves, Valve Positioner, etc. |

|

Sales Point : |

Highly reliable, long life, Simple in construction and maintenance free Ball Valve. |

|

Application : |

For air, water, oil, gas, corrosive chemicals, Combustion equipment, Power Stations, Hydro-Electric, Power Generation, chemicals and petrochemicals industries, Water treatment plants. RO Plants, etc. |

Metal Ball Valves Screwed & Flanged End - 3 Way

|

Sizes : |

15mm (1/2”) to 65mm(2 1/2”). |

|

Body & spring chamber : |

Investment Casted Cast Steel ASTM A216 WCB or Stainless Steel ASTM A351 CF8 (SS304) or CF8M (SS316). |

|

Ball : |

Stainless Steel AISI 316 bar stock. |

|

Diaphragm : |

As per API 607 Std. |

|

Stem and Stem nut : |

Stainless Steel AISI 316. |

|

Ball Seat & Seals : |

Reinforced PTFE/RPTFE. |

|

Body gasket : |

PTFE. |

|

Antistatic device : |

Stainless Steel AISI 316. |

|

Pressure Temp. rating : |

As per BS 5351 Class 300. |

|

Body pressure rating : |

ANSI B16.5 Class 150. |

|

End Connection : |

Screwed/Flanged. |

|

Screwed end : |

15mm(½”) to 65mm (2.1/2”) BSP / NPT. |

|

Face to Face : |

15mm (1/2”) to 65mm (2.1/2”) Flanged to ASME B16.5 Cl.150. |

|

Leakage Class : |

As per ANSI FCI-70-2, Teflon seating Class VI. |

|

Characteristic : |

On-Off. |

|

Temperature : |

155°C. |

|

Actuator : |

Double Acting ‘D’ Spring Return Single Acting ‘S’ |

|

abcd: |

Minimum pressure 5.5 bar, Maximum pressure 8.5 bar |

|

Manual Operation : |

Hand lever type upto ACT-63-D/S Actuator. Side hand wheel from ACT-90-D/S actuator onwards. |

|

Accessories : |

Air lock relay, Valve Positioner (P to P), Position Indicator, Rotary Limit Switches, Proximity Switches, Solenoid Valves, etc. |

|

Sales Point : |

Highly reliable, long life, Simple in construction and maintenance free Ball Valve. |

|

Application : |

For air, water, oil, gas, corrosive chemicals, combustion equipment, Power stations, Hydro-Electric Power Generation, Chemical and Petrochemical Industries. |

|

Note : |

For double acting actuator, pilot air pressure required 4 to 8.5 bar for spring return actuator, pilot air pressure required 5.5 to 8.5 bar. |

|

|