Pramp Automation and Calibration

Category: Flow

Product: Flow Pressure Meters

Sub Product: Orifice Plates

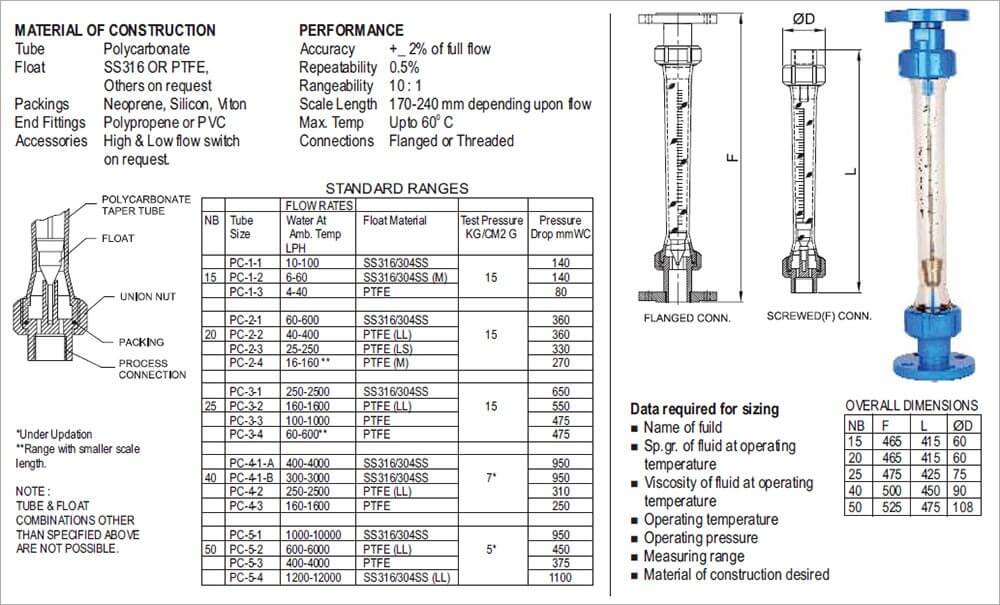

Orifice Plates are most commonly used primary elements for flow measurement in pipelines based on the principle of measurement of 'Differential Pressure' created when an obstruction is placed in the fluid flow, due to increase in fluid velocity.

Orifice Plates cover a wide range of applications of fluid and operating conditions. They give an acceptable level of uncertainties at lowest cost and long life without regular maintenance.

We have fully equipped integrated designing, manufacturing and testing facilities which are amongst the best in the Country. Over the years we have manufactured and supplied Orifice Plates Assemblies to many prestigious projects in the Domestic as well as International market.

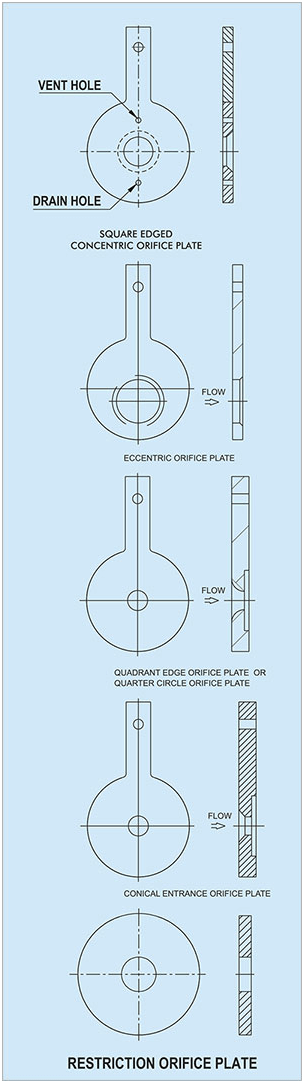

The Square Edged Concentric type of Orifice Plate is most commonly used for flow measurement. This has got features such as simple structure, high accuracy, and ease of installation & replacement. The Orifice Plates are correctly finished to the dimensions, surface roughness, and flatness to the applicable standard. These plates are recommended for clean Liquids, Gases & Steam flow, when the Reynolds number range from 10000 to 10.

We also manufacture Eccentric Orifice Plates, Segmental Orifice Plates, Quadrant Edge Orifice Plates, Conical Entrance Orifice Plates.

Restriction Orifice Plates

The Restriction Orifice Plates are used for reducing fluid pressure and are designed somewhat different from the Orifice Plates that are used for measuring flow rates. They are designed to slip between the piping flanges.

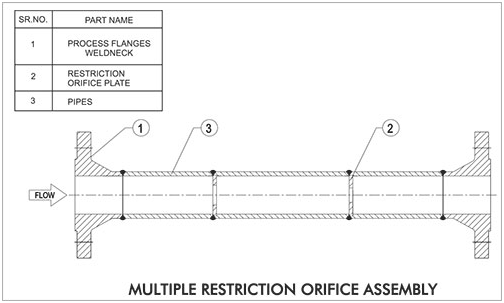

While single Restriction Orifice are often sufficient to meet the requirement, there are situations where limitations arise due to process conditions making the single Restriction Orifice unacceptable. In such situations, use of Multiple Restriction in series is a better soltion.

The foremost consideration in using Multiple Restriction is the pressure drop. Higher pressure drop implies higher velocities resulting in vibration and noise problems. Hence instead of a Single Restrction Orifice Plate, Multiple Plates are used.

The other consideration, particularly for gas flow is that if the process condition indicates that critical flow will occur with the use of single restriction plate, care should be exercised to avoid operating well beyond the critical pressure drop.

Construction of Multistage Orifice Assembly is as shown in the adjoining sketch. End connection is either suitable for butt welding or with end flanges.

|

|

Orifice Flange Assemblies

|

|

Orifice Plate With Weld Neck Flange Union

The Weld Neck Flange is normally referred to as "High Hub" flange. It is designed to transfer stresses to the pipe, thereby reducing high stress concentrations at the base of the flange. The pressure tappings are provided through the flange which are at a distance of 1" from the face of the plate.

Orifice Plate With Slip On Flange Union

The Slip On Flange has a "low hub" because the pipe slips into the flange prior to welding. It is welded both from inside and out to provide sufficient strength and prevent leakage. The slip on flanges are bored slightly larger than the OD of the matching pipe.

Orifice Plate Assemblies With Rtj Holder

Description

The Plate Holder Assembly is a combination of plate holder and an Orifice Plate designed for Ring Tongue Joint (RTJ) Flanges. The plate holder has a function of holding the Orifice Plate and also functions as a gasket to prevent leakage of the process fluid. The plate holder has an oval or octagonal ring for mounting between ring type joint flanges. This metallic sealing system is useful for a fluid of high temperature and high pressure. The pressure tapping system normally is of the flange tap type.

Orifice Plate is screwed t