Pramp Automation and Calibration

Category: Flow

Product: Kone Flow Meter

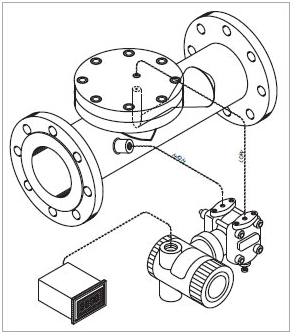

The EUREKONE FLOWMETER is a new differential pressure flowmeter device that accurately measures flow of various fluids over wide flow range than any other conventional differential pressure flowmeter such as venturies, orifice plates etc. The basic principle is Bernoulli's theorem for the conservation of energy in fluid flow through a pipe. The divergent shape of the cone sensor centered in the line, reshapes the velocity profile to create an improved profile. The configuration of a typical EUREKONE FLOWMETER is showing fig. A/B.

The pressure difference between the static line pressure and the lower pressure created just after the cone sensor can be measured via two pressure sensing taps. One placed slightly upstream of the cone sensor & the other in the downstream face of the cone sensor itself and is related to flowrate through the meter.

Accuracy

The EUREKONE FLOWMETER is able to operate accurately over wider flow ranges than any other differential pressure flow meter. An accuracy of better than +1% of actual flow is achievable to the majority of the applications.

Repetability

The EUREKONE FLOWMETER exhibits a repeatability of better than +0.1% the high repeatability creates a very steady output signal. This is because the shape of the cone sensor is specifically designed to dampen the amplitude of the oscillation for the measured pressure field.

Rangeability

The EUREKONE FLOWMETER is more rangeable than any other differential pressure devices because it reshapes and flattens the fluid velocity profile flow rate turndown of upto 10 to 1 are easily measured.

Long Term Performance

The EUREKONE FLOWMETER has no moving parts like bearings & gears, so problems which are typical to rotary meters are eliminated. As the cone sensor has divergent shape, the flow is directed away from the critical edge & the edge is not damaged by foreign solid particles present in the stream. There are no stagnant fluid areas for gaseous build up or solids entrapment as it is in the orifice plate. The performance is therefore unaffected by these common problems.

Signal Stability

The output of the D.P. Transmitter when connected across EUREKONE is highly stable as compared to output of D.P. Transmitter when connected across orifice. Due to special design of cone sensor, the flowmeter does not allow debris, condensation or particles from the fluid to accumulate.

Secondary Instrumentation

The EUREKONE FLOWMETER works with any standard Differential Pressure Gauge, D.P.Transmitters, Manometers, etc. The EUREKONE FLOWMETER can be incorporated into an existing system without having to invest in new instrumentation. The EUREKONE FLOWMETER combined with D.P.Transmitter and flow computer forms a complete system to meet stringent applications.

Installation Requirements

|

The velocity profile is reshaped by the cone sensor & hence there is no need for long upstream straight pipe lengths. Typically installation piping requirements are about 3 Diameter Upstream & 5 Diameter Downstream for all type of pipe fittings present upstream. The EUREKONE FLOWMETER may be installed in either horizontal or vertical piping.

Applications

The EUREKONE FLOWMETER finds application in the measurement of flow of Water, Steam, Air, Nitrogen, Hydrogen, Coke oven gas, Propane, Argon, Neon, Exhaut Gases & many more fluids.

Specific Applications

- Monitoring air / water / steam consumption

- Wet gas measurement

- Oil measurement

- Condensate measurement

- Measurement of liquid containing particles is also possible

- Any media which is difficult to handle by other differential flow meter can be measured