Pramp Automation and Calibration

Category: Flow

Product: Flow Switches

Sub Product: SWAS System

STEAM & WATER ANALYSIS SYSTEM (SWAS)

SWAS is designed to monitor the purity of boiler feed water and steam. This very much important in case of steam boiler, steam turbine, condenser and other steam equipment.

On line analysis of critical parameters such as pH, Conductivity, Chloride, Sodium, Silica, etc. is helpful to prevent damage due to scaling and corrosion. In case of Power plant SWAS plays a vital role, avoiding mechanical damages, deposition on turbine blades & corrosion in pipe line.

Sensors & analysers can not withstand high temperature & high pressure SWAS processes sample at high temperature & high pressure & reduces temperature & pressure to a level so that all these critical parameters can be measured.

SWAS in general comprises of :

- A Wet Panel: where the Temperature, Pressure & Flow of sample is conditioned and regulated. All sensors are also a part of this panel.

- A Dry Panel: where all the on-line analyzers are located. Cables from sensors gets connected to this panel.

The panel construction can be open frame, closed from front & open from back, or fully enclosed type.

Main Components of SWAS

- Sample Cooler

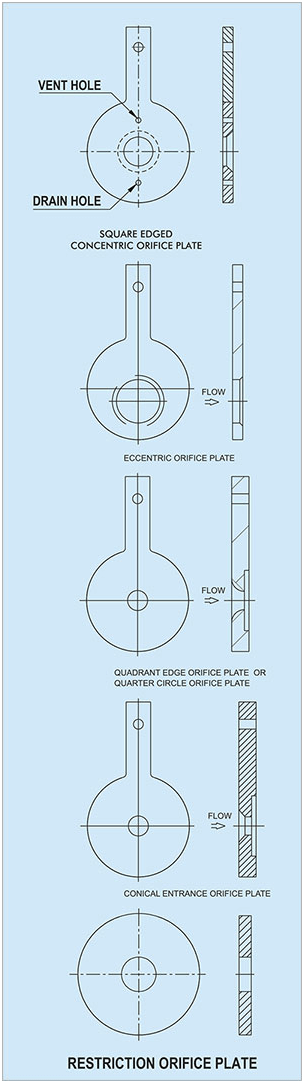

- Variable Pressure Reducing Element

- Back Pressure Regulator

- Thermal shut off valve

- Sensors & analysers

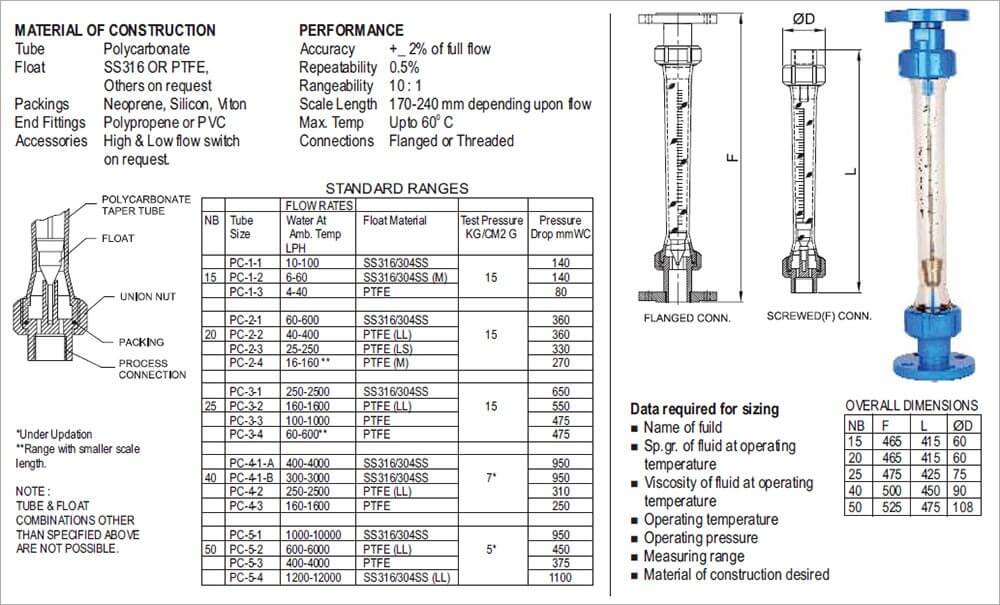

- Rotameters

- Necessary valves & fittings

Inputs required from customer

- Number of samples to be connected to SWAS

- Temperature & Pressure of each sample

- SWAS requires cooling water from customer. Temperature, pressure, flow, chloride content(ppm), calcium hardness(ppm) of cooling water.

- If you can provide chilling water, then temperature, pressure, flow, chloride content(ppm), calcium hardness(ppm) of chilling water.

- Parameters of sample to be measured eg. pH, conductivity, dissolved oxygen, silica etc.